COMPACTION ANALYSER (SCADA)

COMPACTION ANALYSER (SCADA)

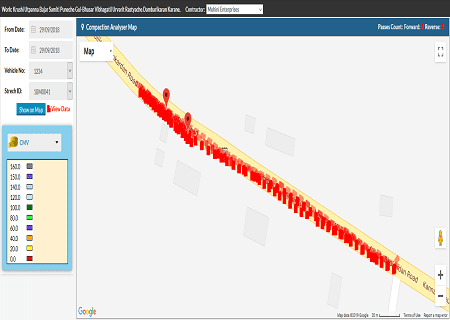

Vasundhara's Compaction Analyser offers a comprehensive solution for planning, measuring, controlling, documenting and analysing compaction process. It also facilitates the real-time compaction monitoring and timely adjustments of the compaction process in order to attain high quality and uniform concrete mixture.

Features

| Record the no. of forward & reverse passes with location, time, temperature, compaction details | Measure & record rolling surface temperature by using server-based intelligent system | ||

| Graphical display supported by software to monitor & record data onsite | User and operator friendly display | ||

| Simulator mode present in all types of rollers | Storage & analysis of compact meter data | ||

| Adjustable resolution / brightness for display | Report generation from the server in PDF format |

Advantages

| Comprehensive, homogenous compaction measurement | |

| Quick installation & ease of operation | |

| High compaction quality with increased productivity | |

| Analyses can be carried out even years later | |

| Multiple access to data through server based support | |

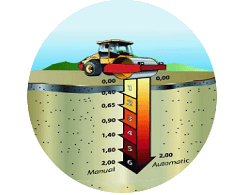

| Improved depth of compaction achieved by continuous record ofmaterial stiffness value | |

| Simple and secure data archiving |

Product Technology

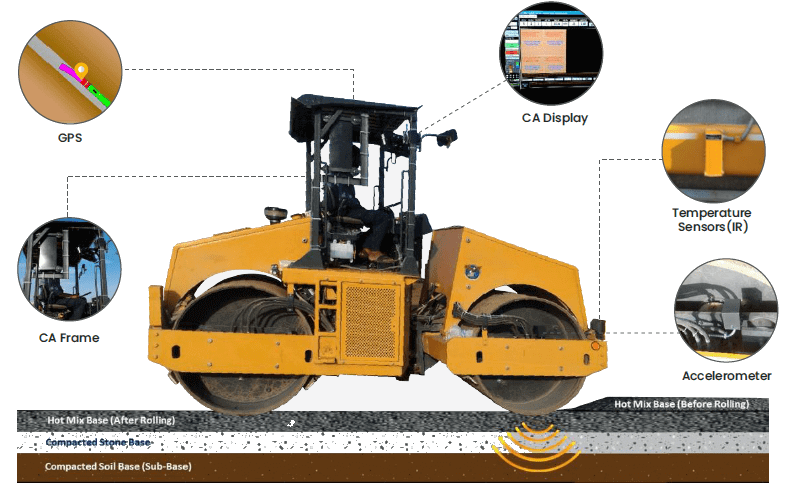

Vasundhara compaction analyser through its seamless integration

with SCADA makes every pass of the roller count with compaction

details.

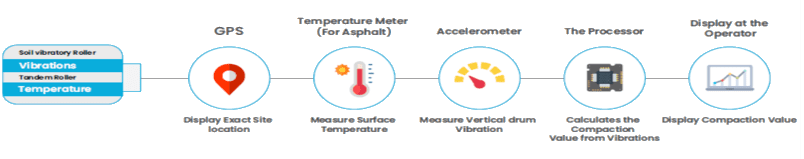

GPS: Ruggedized GPS system provides precise

geographical location of each run along with accurate pass

count. Compaction meter: State of the art accelerometer is

mounted in or about the drum to monitor applied compaction

effort, G-force vibratory frequency, and compaction material

response. It delivers perfect surface stiffness value that

ensure the meeting of regulatory intelligent compaction

standards.

Temperature Meter: On asphalt

rollers, this is supplemented by two infrared temperature

sensors mounted at both ends of the roller to register surface

temperature of the asphalt. Vibratory compaction of hotmix

temperature with 0 to 400 degree Celsius and with ±1% ranges

can be monitored.

Display: The compaction

result (Material Stiffness Value) is continuously displayed on

the computer screen of the operator. At the same time, the data

is uploaded on Client as well as Vasundhara server for

monitoring and documentation purpose. Connectivity to the SCADA

software allows 24 X 7 access to the data.

Why Vasundhara

Compaction is one of the most important processes in roadway construction. It is crucial to attain high quality and uniformity of concrete materials, which in turn ensures long-lasting performance. Concrete materials often possess optimum densities that ensure adequate support, stability, and strength Vasundhara offers the best IC aids to achieve these densities uniformly throughout this process.

SCADA Features Provided

It's not too often that quality and efficiency go hand in

hand, but with our SCADA system this is exactly what happens.

Compacting jobs gets completed faster and more accurately.

Our SCADA system helps measuring the compression measuring

value (CMV) for,

Drum Accelerometer value

Human machine interface

GPS, GIS

Number of passes and speed

.png)