Service is Our Strength

Vasundhara, based in Pune, is a dynamic custom software services provider fostering a diverse workplace that enhances business and encourages cross-cultural collaboration. Our seasoned team brings extensive expertise in both software and hardware development, navigating various platforms, languages, and tools.

Our strength lies in profound domain knowledge and a proven track record of conceptualizing, exploring cutting-edge technologies, and delivering comprehensive solutions. With a commitment to excellence, we assist clients in identifying the right solutions to effectively address their challenges.

.png)

.png)

Automation

Delivering technology blended with SCADA driven functional automations through systems integration and wireless applications..

SPM

Our SPM division is a dynamic organization comprising of highly skilled and experienced engineering and management professionals.

Software

Whether your business is technical or commercial, we offer customized software applications that address most of your business processes.

SCADA

Supervisory Control And Data Acquisition, a computer system for gathering and analyzing real time data of plant or equipment in industries such as construction, water flow control, energy, vehicle monitoring and transportation.

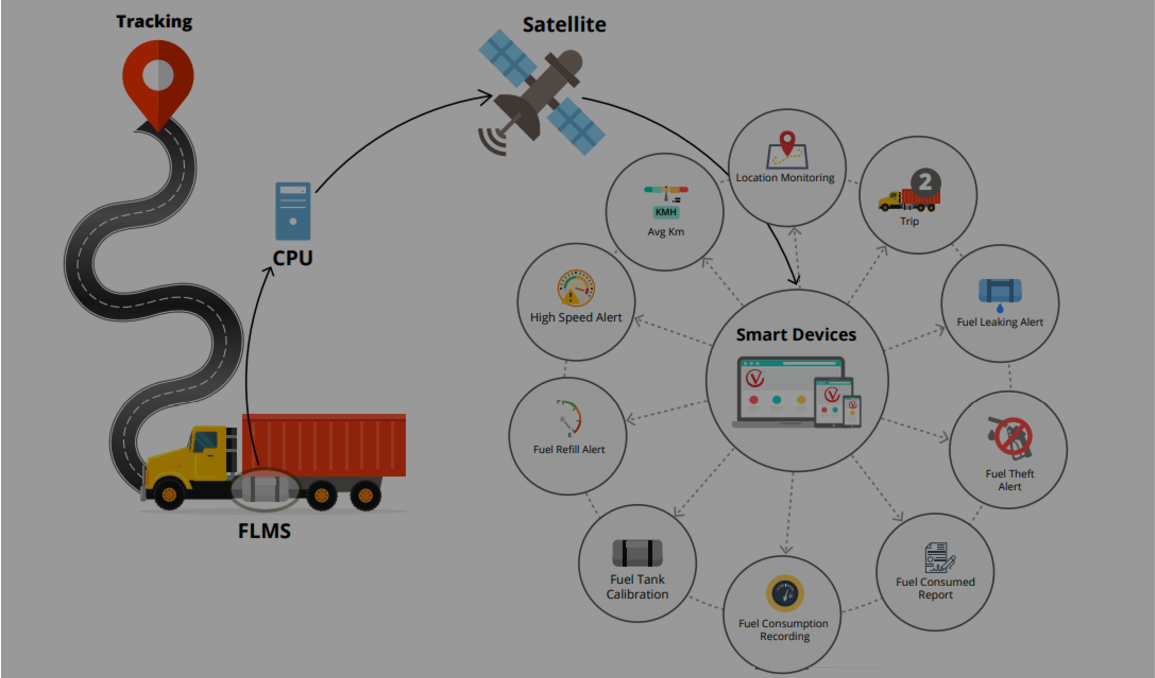

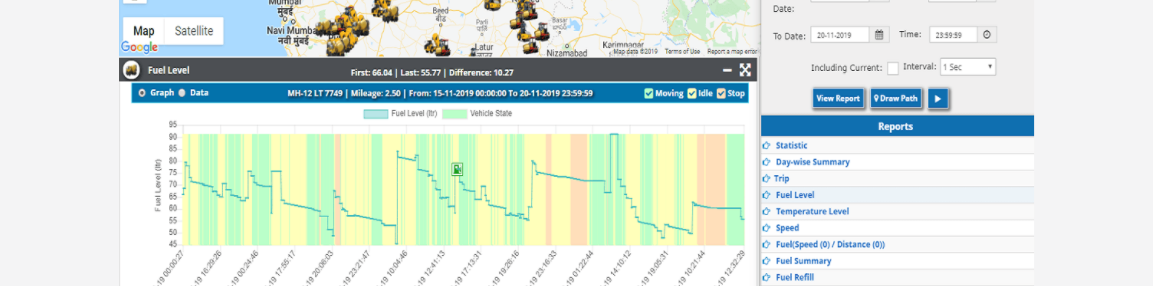

VIPL - VMTrack

Fuel monitoring system helps to keep check on consumption of fuel and generating reports

Compaction Analyser system

Vasundhara's Compaction Analyser offers a comprehensive solution for planning, measuring, controlling, documenting and analysing compaction process.

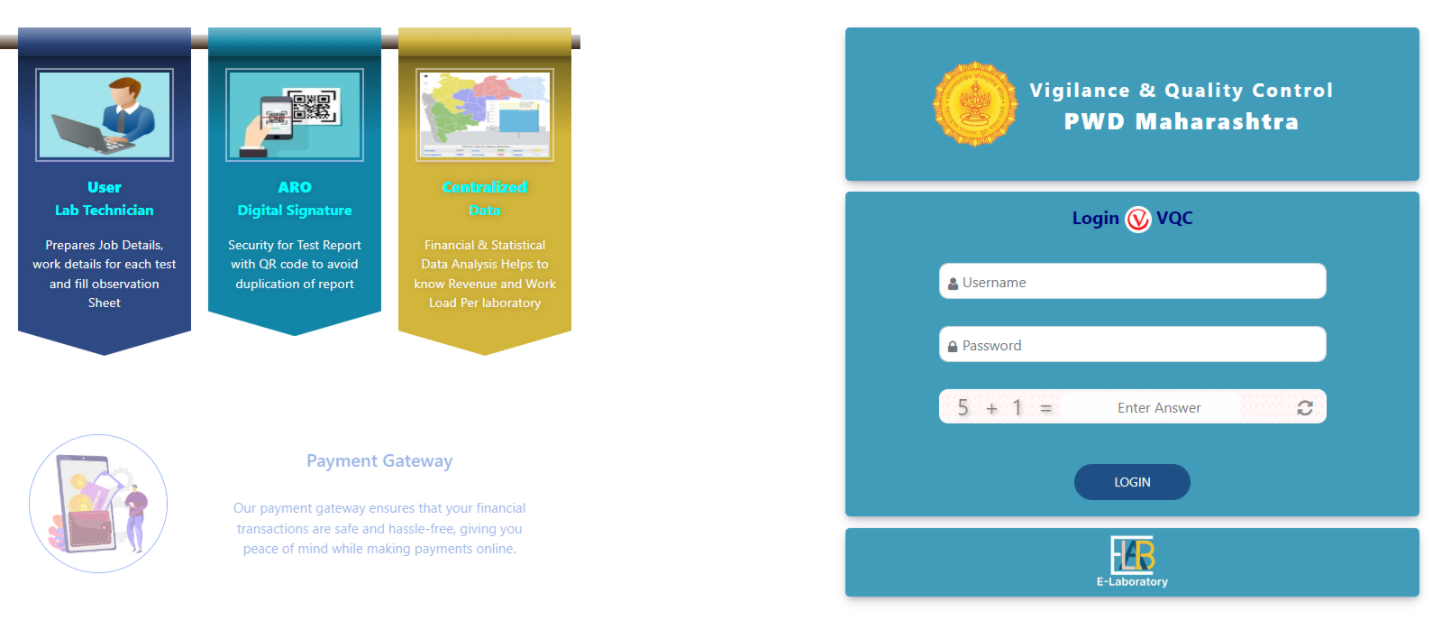

E-LAB

Your Comprehensive Solution for Construction Material Testing Laboratories.

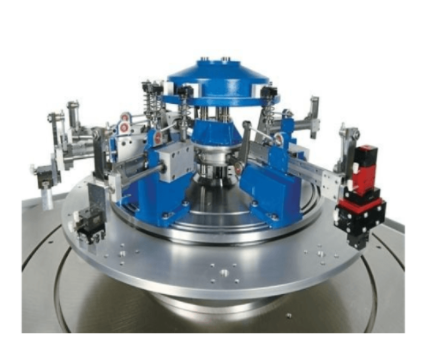

Special Purpose Machine

Our SPM division is a dynamic organization comprising of highly skilled and experienced engineering and management professionals.

Compression Testing Machine

The Compression Testing Machine is intended to meet requirements of consistent means to check concrete block for its compressive strength. Vasundhara is a leading company in the field of fully automatic CTM with enhanced digital display features. Different variants of CTM are calibrated as per NCB standardization. Deployed to test concrete cube, beam and cylindrical cubes, the machine plays an important role in identifying quality control for concrete. The compression testing machine also aids evaluation and implements concrete strength tests with good accuracy

Principle of Operation of Compression Testing Machine

Vasundhara’s PLC based CTM has a three-phase induction motor controlled by PLC based circuitry. This facilitates

- Automatic pace rate control

- Data logging

- Data printing

- Load hold

It consists of loading unit, an electrically operated hydraulic pump, and an intelligent pace rate control. The two-speed pump allows fast approach of platens, for daylight closure and allows automatic, precise control over the load application. The operation is user friendly with menu driven interface.

Assorted Features

- Inbuilt SCADA with user friendly or operator friendly operating software.

- Automatic test cycle with standard rapid approach.

- Load v/s time plot and instantaneous load rate Displayed on software screen.

- Advanced software for test control and report generation within seconds.

- Data Acquisition and Control System.

- Ergonomic Design & Self aligning platen

- Safety limit switch to provide a limit to forwarding stroke of RAM/Cylinder

- Max pressure valve to avoid machine overloading.

- Software controlled maximum load value.

- Convenient display of parameter values (load, stroke, and elongations) through real time curves.

- User safety feature like metal door.

- Automatic pace-rate control.

- Loading Accuracy as high as ±1% F.S.V.

Additional Features

- Accurately calibrated dial gauge

- CTM SCADA software to generate report on Site/Lab

- Server based support for testing report

- Precise display to eliminate human errors

- Uniform pace rate as per control knob

- Power Breakdown Protection for Motor and Other Components

- Current pressure and peak breaking pressure is displayed on digital display

- PLC based circuitry to control motors, which achieve precise pressure and accurate reports

- Auto / Manual Control and release valve operation

Advantages

- Wider range of test force measurement

- Long term use

- Compact design

- Rust resistant

- High reliability

- Low maintenance

- Data Backup facility

RMC SCADA

provides turnkey solutions for Batch mix control panel and SCADA to remotely monitor the strength and quality of ready-mix-concrete at all plant locations. Batch sheet linking to respective work. Aggregate (10mm, 20mm, RS, CS), Water, Cement, Fillers. Etc & send real time data to server.

RDM / SLM SCADA

Vasundhara’s SCADA monitors the exact proportion and best quality of all involved components for creating a perfect enduring concrete mix, Perfect composition of materials can be obtained every time & send real time data to server.

BOUZER / SPRAYER SCADA

Bouzer/Sprayer SCADA monitors temperature of Bitumen at the time of spraying as well as speed of vehicle, location of vehicle and send real time data to server.

Water Curing SCADA

SCADA system can show the exact amount of water used for curing purpose & send real time data to server.

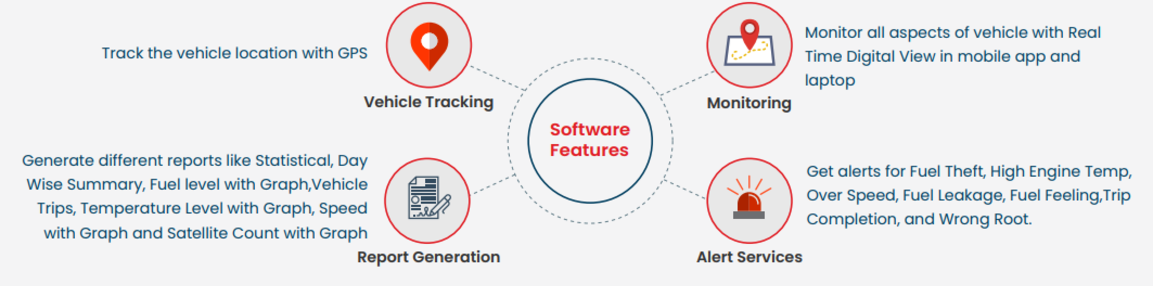

VTS (Vehicle Tracking System)

Our GPS tracking is a Fleet Management Solution that focuses on fleet monitoring and tracking. It can be effectively used for remote monitoring from any device.

- Alert pre-defined areas

- Wrong routes alert

- Monitor vehicle speed

- Ignition / AC status

Rectangular House Near Italy

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut. magna aliquam erat volutpat enim ad minim veniam. Duis autem vel eum iriure dolor in hendrerit in.

- Clients: Ethan Hunt, John Doe

- Completion: February 5th, 2019

- Project Type: Villa, Residence

- Architects: Logan Cee, Paul

- Budget: $1 200 000

Special Purpose Machine

Our SPM division is a dynamic organization comprising of highly skilled and experienced engineering and management professionals. The core team comprises dynamic and experienced technocrats who have successfully handled process automation projects, designing and fabrication of special purpose machines at large scale. Our core strength lies in our ability to think out of box when it comes to automation of traditional systems. We always think big and explore the possibilities to eliminate the manual processes by applying our skills and technologies. We have emerged as one of the most sought special purpose machines manufacturers in India in our segment due to our extensive knowledge and diversified industrial experience.

CTM Machine

We manufacture range of CTM machines used for testing the strength of concrete cubes. These machines are easy to install, commission and use. Vasundhara is a leading company in the field of fully automatic CTM with enhanced digital display features. Different variants of CTM are calibrated as per NCB standardization.

2.png)

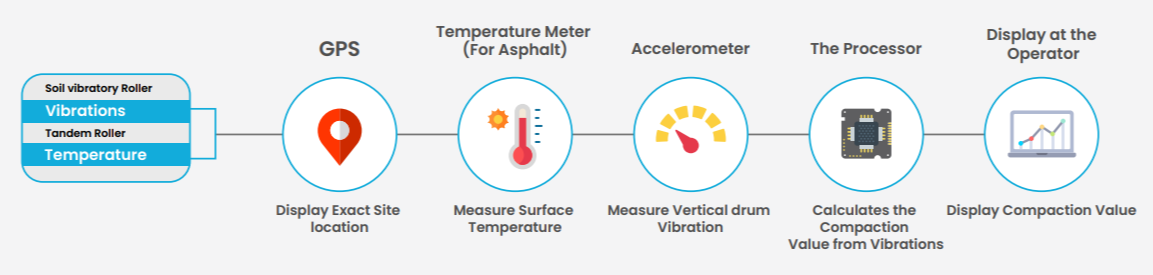

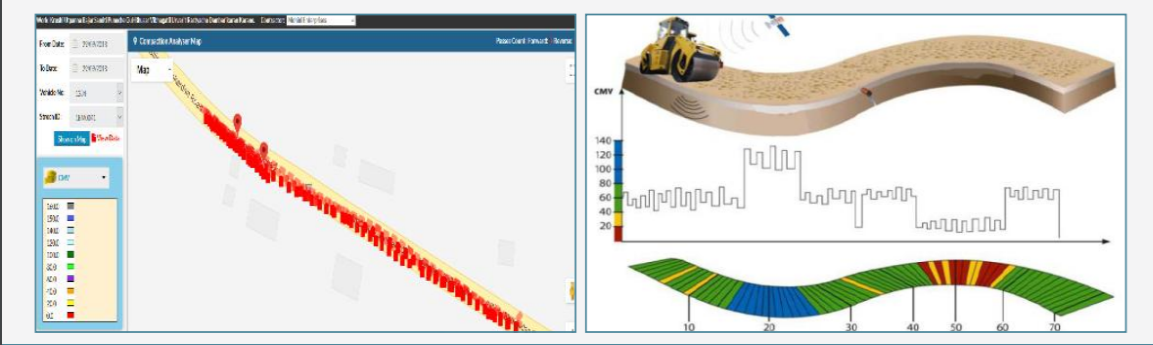

Compaction Analyzer

The process of compaction in pavement and subgrade material is a method of mechanically induced stress applied repetitiously to achieve a desired density to promote both short and long term performance. Compaction Analyzer refers to the compaction of road materials, such as soils, aggregate bases, or asphalt pavement materials, using modern vibratory rollers equipped with an integrated measurement system, an onboard computer reporting system, Global Positioning System (GPS) based mapping, and optional feedback control. CA rollers facilitate real-time compaction monitoring and timely adjustments to the compaction process by integrating measurement, documentation, and control systems. CA rollers also maintain a continuous record of color-coded plots, allowing the user to view plots of the precise location of the roller, the number of roller passes, and material stiffness measurements

Assorted Features

- Record the no. of forward & reverse passes with location, time, temperature, compaction details.

- Measure and record rolling surface temperature by using server-based intelligent system( for tandem roller).

- Analysis and storage of data received by compaction meter.

- Storage & analysis of compact meter data.

- Adjustable resolution / brightness for display

- Report generation from the server in PDF format

- Detail analysis report of compaction with the server-based system

- User and operator friendly display

- Simulator mode present in all types of rollers

- Graphical display supported by software to monitor and record data onsite.

Advantages

- Comprehensive, homogenous compaction measurement

- Quick installation and ease of operation

- High compaction quality with increased productivity

- Analysis can be carried out even years later

- Multiple access to data through server based support

- Simple and secure data archiving

- Improved depth of compaction achieved by continuous record of material stiffness values

- Proper compaction achieved using report generated by compaction analyzer

- Reduction of highway repair costs & other costs due to avoidance of claims

Compaction Analyzer Integration with SCADA for Quality and Efficiency

Vasundhara Compaction Analyzer through its seamless integration with SCADA makes every pass of the roller count with compaction details. This makes compacting jobs to complete faster with more accuracy. Our SCADA system helps in measuring the compression measuring value (CMV) for

- High frequency, low frequency and amplitude

- Drum Accelerometer value

- Human machine interface

- Processing control unit

- GPS, GIS

- Number of passes and speed

E-LAB

Lately it is recommended to have one centralized system that keeps, maintains and updates all the activities related to your school of reputation. The centralized system provides you simplified access to complex business processes for taking decisions on planning, implementation and review of school activities.

Conduct Test For

- Embankment Field Density

- Moisture Content

- Specific Gravity

- Grain Size Analysis

- Compaction

- Permeability

- Sieve Analysis

- Cement-Fineness

Features

- Provide multiple dashboards according to User.

- Online assign test to Test Centers by Junior Engineer.

- Provide Digital Signature facility to ARO.

- User access control.

- Multi-tasking.

Reports

- All Test and Observation Reports conducted in the lab.

- Financial

- Daily Revenue Collection.

- Test wise Revenue Collection.

- Revenue Details.

- Online Statement For PVT Job.

- Report For Advance.

- Job Completion Report.

- Receipt Details.

- Fail Test Report.

- Consumption

- Consumption Report.

- Consumption Details.

- Consumption Summary.

- MIS

- Statistical Report.

- Test Statistical.

- MPR.

- Revenue & Test Line Chart.

- Cumulative Revenue & Test Line Chart.

- Test Pie Chart.

- Job Statement.

- Mix Design Details.

- Test & Job Amount Summary.

- Revenue Summary.

- Category wise Summary.

- Control Register.

- Mail Statement.

Types of Users

- Super Admin.

- Lab Admin.

- Lab User.

- ARO.

- JE (Junior Engineer)

- PWD Officers (Post wise).

- Contractor

.png)

(020)-29511773

(020)-29511773

7720064501

7720064501